R. McMahon Watchmaker's restoration centre. We have the best equipped vintage Rolex service workshop and vintage OMEGA repair workshop in Adelaide, South Australia.

Independent qualified watchmakers, vintage Omega and Rolex experts. Custom in-house watch manufacture. Complicated machinery manufacture and process engineering consultants.

Tonsley Innovation District.

Prototype manufacture and custom watch manufacture.

1 Tonsley Boulevard,

Tonsley SA 5042.

and

McMahon Micro Machining

Mawson Lakes, South Australia.

Adelaide University and University of South Australia Precision Micro Engineering Centre and CAD design studio, micro machining watch movement manufacture centre. Medical and aerospace design, prototyping and testing. Small mechanical and electro/mechanical device manufacture. Process engineering advice.

Strictly by appointment only.

By appointment only. Please book by email or text one of the numbers provided. Entrance at car park level glass sliding door. If my parking marked R. McMahon are being used by SA Health staff please feel free to use the loading zone in front of the glass door entrance to my workshop.

BY APPOINTMENT ONLY.

Bookings between 10 am and 4 pm weekdays.

For booking information please click for an email link here, it is the best way to contact us. info@rmcmahon.com.au

Alternatively book an appointment by text on 0404117186 or 0403586850.

WE ARE NO LONGER ACCEPTING RESTORATION FROM INTERSTATE. LOCAL RESTORATION ONLY.

We do NOT offer watch valuations or advice on watch authentication.

Please note our minimum service charge is $950.

We do not do part repairs or minor repair. Please see our Omega and Rolex service estimate page on the website.

We only specialise in VINTAGE OMEGA and Rolex restoration.

Antique pocket watch restoration service for our existing clients only (Minimum charge is $1,500).

Custom watch manufacture to order.

Please email to book appointment times - richard@rmcmahon.com.au

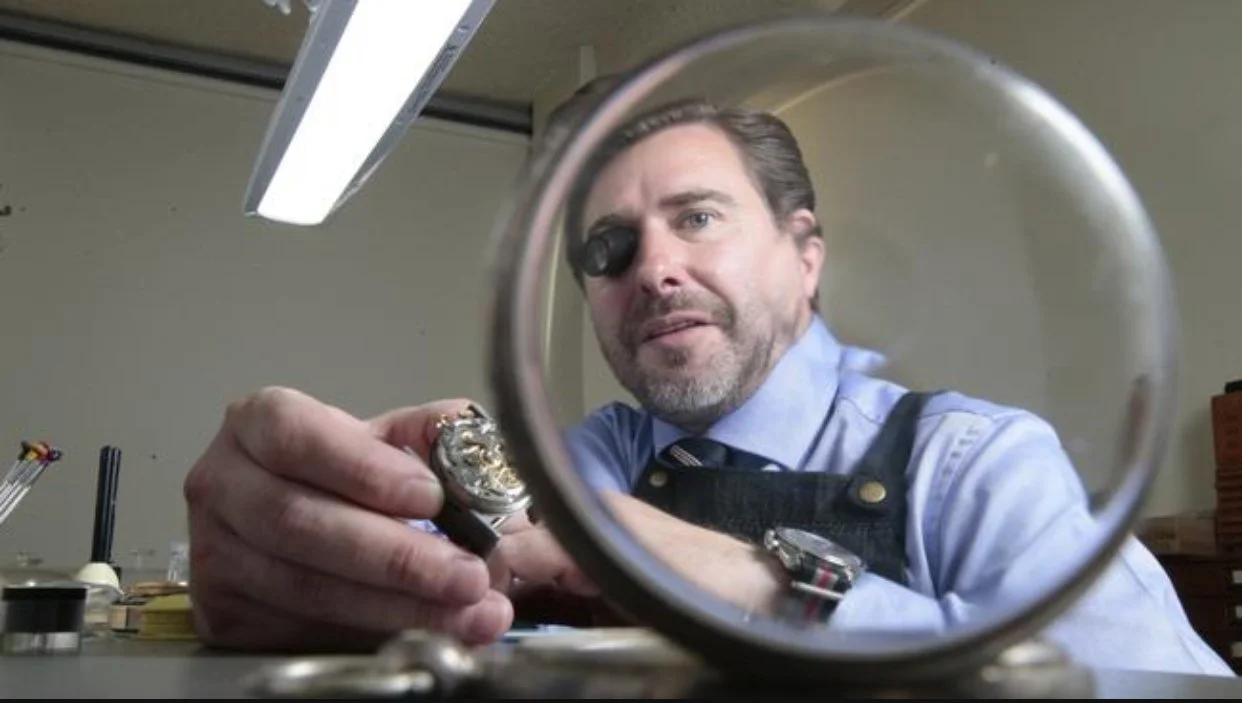

Master Watchmaker Richard McMahon from McMahon Watchmakers and McMahon Micro Machining. Industry Representative with the University of Adelaide and University of South Australia. Micro machining expert specialising in device prototyping for the medical and defence industries. Some people may not know the very close relationship between medical and watch prototyping and manufacture. I have had the opportunity to work in both industries and design and build both complete watches and electro mechanical medical devices. They both use the same machines, and design processes. Sometimes similar materials like stainless steel and titanium Richard McMahon machines every day. The only difference being testing and certification before full scale production. Richard took part in this years Microengineering Winterschool as Speaker for the ANFF UniSA. Tonsley Innovation District and Adelaide University, University of South Australia Mawson Lakes Future Industries Institute machining workshops and CAD design centres. Combined with our precision watch movement manufacturing machinery stretching back 160 years combined with the latest machinery used by the best Swiss manufacturers like Willemin-Macodel multi axis mill, DMG Mori and FANUC Robodrill , we are in the micro machining centre manufacturing movement parts and cases others in Australia simply can’t. It’s more than just buying the equipment, it’s having 35 years professional experience in the master watchmaking global sector that is important. Helping to bring manufacturing back to Australia for the next generation of micro machinists. Buy genuinely Australian manufactured products, and support our goals to put Australian watchmaking on the world map.

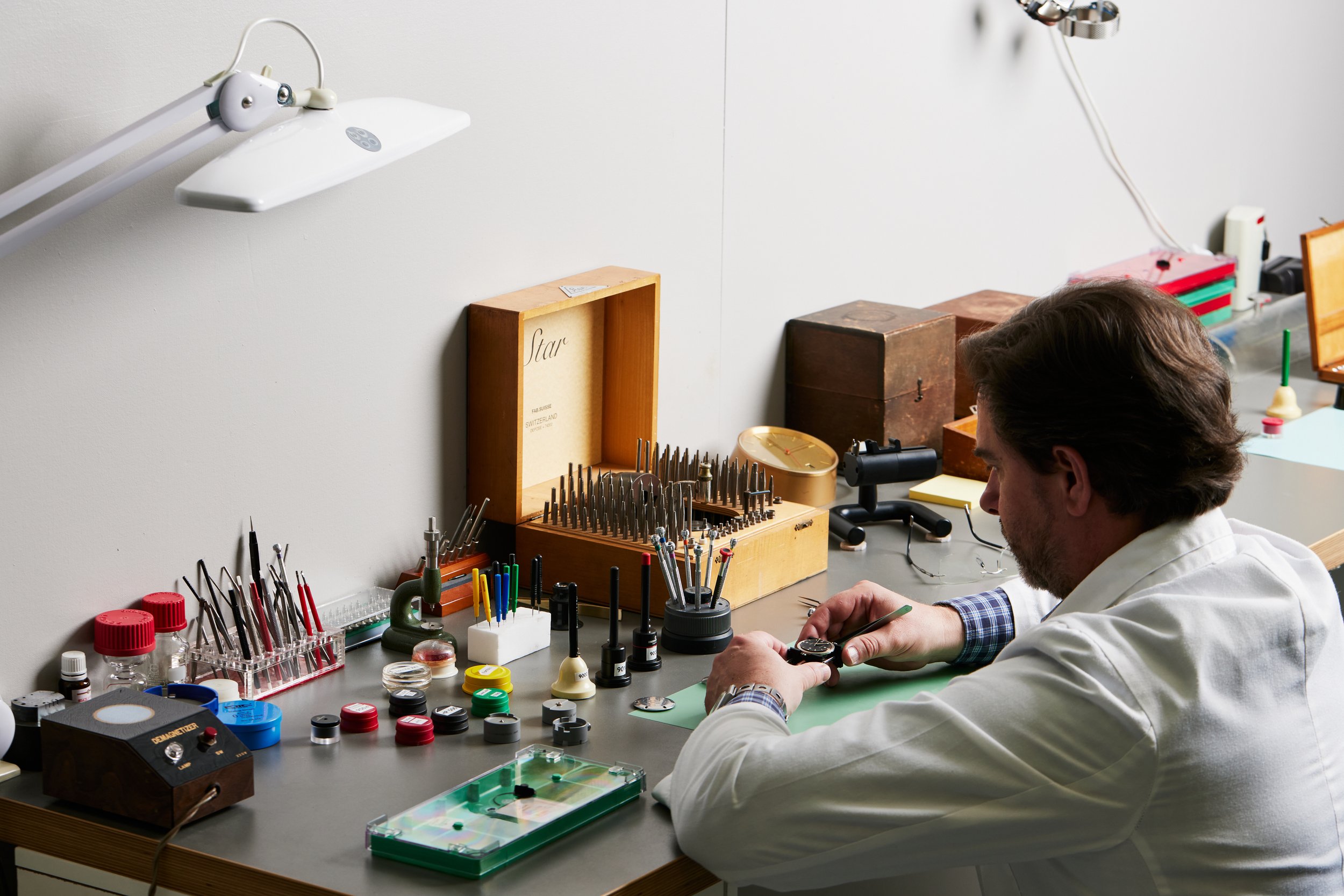

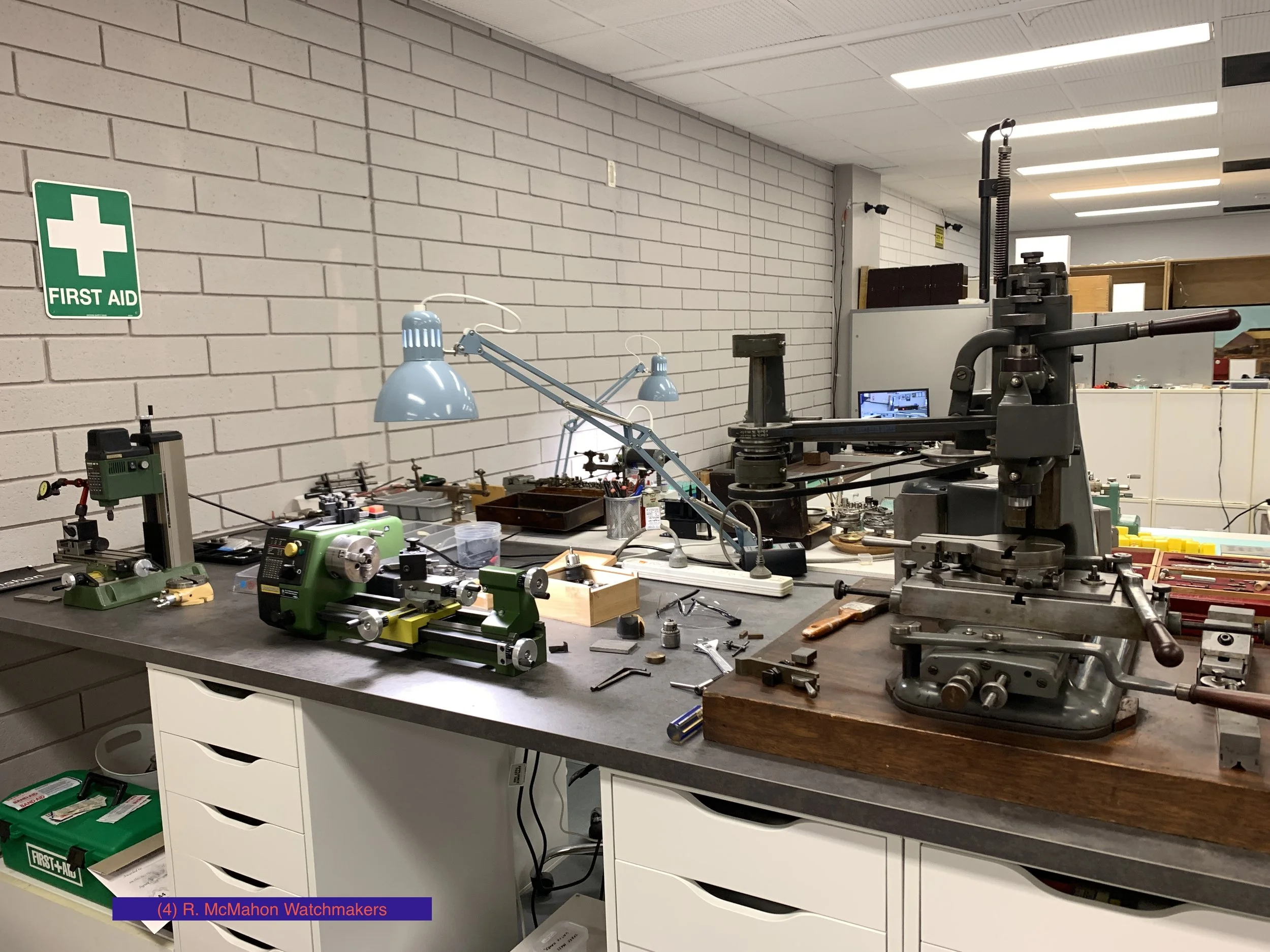

Our Tonsley Innovation District prototyping workshop and micro machining parts manufacturing centre Just one of our three micro machining and device prototyping centres in South Australia. Process engineering advice for prototype testing and development. A combination of manual and CNC precision mills and lathes used for making main plates, bridges, wheels, pinions, escapements and balance wheel assemblies. We build movements, watch cases, dials and hands in our workshops and micro machining centres, not simply importing and branding as Australian like most others. Richard McMahon is a true Master Watchmaker designing in partnership with our clients, manufacturing to international standards.

Wrist and pocket watches hand made to order in our Tonsley, South Australia based workshop and UniSA Mawson Lakes Micro Engineering workshops by Master Watchmaker Richard McMahon. More details below on our website. We hand make our own enamel dials, cases, hands and finish high grade Swiss movements or our own custom manufacture on offer. Custom builds in stainless steel with a manual wind movement and hand made enamel dial start at $25,000 (These models ending with last orders December 2025, custom movements Tier 1 and 2 from January 1 only). We have in our Tonsley workshop manufactured, sold and shipped all of our 12 limited edition Tonsley watch series. We have delivered the last of our 12 Tonsley watches manufactured and now accepting further custom commissions. One custom pocket watch has been built and delivered in 2025 and another 2 custom manufactured wristwatches are at the final build stage for clients. We build our own cases, dials, hands and in-house movements, we endeavour to manufacture as much as possible in our watch manufacturing centre and micro machining workshop, currently for our top tier movement at 95%. We are about local manufacture and future local Australian jobs, not buying in cases, dials and movements to sell as Australian, buy Australian manufactured goods and support local business. There is a difference between marketing claims and genuine watch manufacture, see our manufacturing workshop photos on this website.

International master watchmaker Richard McMahon with over 34 years experience as a qualified professional watch manufacturer and restorer. Trusted official restorer for JLC, Cartier, Breitling and Rolex agencies in the UK. Now based in the Tonsley Innovation District South Australia.

Expert Rolex service and restoration. The best equipped Vintage OMEGA service workshop in Adelaide. Proudly independent qualified watch restoration experts.

Micro machining experts, combining technical commonality between watchmaking and medical device design prototyping, building and designing locally, here in Adelaide, South Australia.

Tonsley Innovation District prototype

engineering centre and Mawson Lakes Adelaide University design studio and micro machining facility McMahon Micro Machining.

Modern ultrasonic cleaning for high grade current models of high grade watches. Gentle cycle cleaning machines for vintage and antique Rolex and Omega vintage watches. We have the most experienced and best equipped vintage watch restoration centre in Adelaide, South Australia. Precision cleaning of aerospace instruments, medical devices and precision machinery service.

GPS calibrated precision timing equipment. The industry benchmark for watch regulation and diagnostics. OneOF accuracy Swiss machine.

Our workshop.

Richard McMahon trained as a horologist first in Adelaide starting in watch repair in 1989 completing his apprenticeship in 1994. In 1994 was accepted as an Executive Member of the Horological Guild of Australasia (No. 5120). In 1995 moving to Clocks of Distinction in Sydney for 5 years. In the year 2000 moving to London and working on Bond Street as a certified contractor for Cartier and as the preferred vintage restorer referrals from Rolex St James square, specialising in restoring models Rolex were no longer servicing at the time, (Rolex Submariner 6200, 6204, 5508 and 5513. Rolex GMT 6542. Bubble back Oyster Rolex and Prince models). We were the contract official restoration workshop for JLC complications and Breitling chronographs at Somlo Antiques in Piccadilly London, the leading authorised vintage Omega restoration centre in the UK, for rare models sent from Australia and parts of Asia boutiques.

Specialising in complicated movements, Richard is a vintage watch expert, specialising in chronographs, repeating watches and hand-makes components such as balance staffs and winding stems, which have long since gone out of production. Richard returned to his hometown of Adelaide, South Australia in 2015 and established a vintage watch restoration centre in Adelaide, Tonsley Innovation District. R. McMahon Watchmakers has quickly expanded over the interceding years and now boasts some of the most advanced watchmaking equipment in Australia. Richard McMahon has worked as a consultant and prototype developer for large watch companies in Switzerland to assist complicated movement development and process engineering for new high end luxury watch brands.

Not just a watch repair shop, a watch restoration centre. Vintage OMEGA service (we no longer work on Co-Axial OMEGA or quartz) and Rolex repair experts.

Richard McMahon trained in micro machining in the 1990’s starting with precision Swiss and German milling and lathe machinery. Later training in the use of laser scanning and laser welding and parts manufacture. Over the last 20 years Richard McMahon has completed many small machine manufacture projects for the medical, defence and aerospace industries. In recent years advanced CNC micro machining, training in CAD design with Inventor and Fusion at our design studio and partnering with the Future Industries Institute at Adelaide University and with the Australian National Fabrication Facility. Now bringing these skills from over 35 years to South Australia for small scale prototyping and testing of complicated mechanical and electro/mechanical machinery. Photolithography and circuit manufacture. We have access to multiple levels clean rooms at both Tonsley and Mawson Lakes machining centres, with spaces available for assembly with ANFF.

Not just watch manufacture, servicing and advising start ups to large engineering companies, right here in South Australia. Helping to bring manufacturing back to Australia. Richard McMahon spent decades manufacturing from scratch all parts in high end watch restoration, for a few Swiss companies under licence as an official restoration expert and consultant. Main plates, wheels, pinions and escape wheels. Over the last 20 years Richard McMahon has used these skills to manufacture complete watches. This journey has been a 35 year story to get to this point, with commissions now completed for 2 models the building concentrating on custom complication commissions is what an exciting prospect to have your own in-house chronograph, repeater or alarm watch.

Richard McMahon has given much time to the training and mentoring of many micro technicians and watchmakers learning micro machining equipment in a safe and exacting manner. As a consultant Richard McMahon has set up engineering centres in Australia and Europe for small parts manufacture and prototype development for medical, defence industries and precision watch parts manufacture. Richard McMahon has found training and educating the next generation of machinists and prototype developers rewarding and an important part of contributing to Australia’s domestic manufacturing industries.

Richard McMahon has rare experience from his time in London as an expert consultant and preferred restorer for Vintage OMEGA and Rolex. Certified restorer of Cartier, JLC and Breitling while at Somlo antiques in Piccadilly London manufacturing watch parts and completing restoration these companies no longer carried out in-house. He is a fully qualified watchmaker and restorer with over 34 years experience bringing these skills back to Adelaide, South Australia. We offer service most other workshops in Australia are unable to.

We carry one of the largest stocks of genuine Omega parts in Australia.

Our Adelaide watch restoration workshop in the Tonsley Innovation District is well equiped with international standard modern and vintage equipment to ensure the very best in Swiss vintage watch repairs.

Due to our busy workload we are only specialising in Vintage OMEGA pre-1970 and vintage pre-2015 Rolex watch restoration. 2 years warranty.

Watch tester for diagnostics on automatic winding watches. Testing for timekeeping and power reserve on vintage manual wind models of Omega and Rolex.

Latest pressure test diagnostic equipment. Negative pressure test for slim dress models and vintage pieces. Programmable tests up to 10 bar for hard case dive models. We use a professional wet tester for professional dive models past 12 BAR.

Magnetic diagnostic machine for identifying magnetism and the location of the flux. The watch can be demagnetised and then re-checked for faults. This is the modern proven method. Most workshops just demagnetise without knowing the result. Magnetic testing and pressure testing for small medical and defence devices. Quality control and testing. We offer precission assembly services to medical and defence contractors, we have for decades provided complex, clean precision small to medium device manufacture and assembly. We have acces to ISO 5 and 6 cleanliness rated clean rooms if required. We are also experienced at operating in 14644 if onsite remote expert assistance is required.

What clients are saying. Just some of many customer reviews. We specialise in looking after serious watch collectors especially vintage Rolex and Omega enthusiasts.

“Outstanding service, sound professional advice. Thanks Richard”

“Outstanding service, amazing knowledge of watches and watch repairs. I wouldn’t trust anyone else with my collection, an absolute professional. I always love to see the the great vintage watches available for sale too, this is the place to start for a pre-loved classic.”

Service information

We give priority to vintage OMEGA and Rolex service. Our standard service time is 10 days, we will inform you after quoting about parts availability and service time. Minimum 2 months on complications like vintage minute repeaters and complicated chronographs. We do request a 50% deposit on proceeding on some types of restoration work. We are still specialising in vintage OMEGA and all Rolex.

Vintage Breitling, Cartier, Patek Philippe and Vacheron Constantin service depending on age and model, please contact us to check if we can help as we prioritise Omega and Rolex restoration for our existing clients only. We have a large stock of parts for these models, and are able to restore some early models other workshops are unable to. Our vintage watch repair workshop contains a combination of cutting-edge and traditional watchmaking equipment. We restore wristwatches to exacting standards. We do not service basic quartz or fashion watches as this is not our area of watch repair. Where possible, R. McMahon Watchmakers source original parts for the sympathetic and authentic restoration of valuable time pieces but are also able to custom-make components that have long since lapsed in production or become extinct on the market. For example, some early Rolex and Cartier parts are no longer available, as a qualified and trusted restorer will manufacture parts in my workshop here as I was trusted to do by the official service centres while a senior, certified restoration expert for these companies in London.

Expert restoration of Rolex Submariner, Rolex Sea Dweller, OMEGA Speedmaster Professional and OMEGA Seamaster in our workshop regularly.

We provide 12 month warrantee on Omega and Rolex service repairs. All other brands and types of watches 12 months warrantee is given unless stated otherwise when quoting on the watch repair.

Founder of R. McMahon Watchmakers, Richard completed a four-year apprenticeship in 1994 and is a co-author of the watchmaking industry standards of servicing for the Federal Government of Australia.

Vintage mechanical OMEGA service and restoration, Vintage Rolex service and restoration. Richard was certified by Cartier UK in 2001 at the Bond Street London restoration centre. JLC UK and Breitling restoration UK as an official restorer while at Somlo Antiques. Rolex referral expert while in London from 2001 officially by Rolex St James square. R McMahon Watchmakers is an independent business and has no association with Rolex Australia Service or Swatch Group Omega AG.

In 2025 Richard McMahon was accepted as an Industry Representative for the University of South Australia and Adelaide University at the Future Industries Institute. Speaker at the Microengineering Winter School for ANFF at the University of South Australia. We will be helping to mentor and train the engineers and micro machinists of tomorrow. With access to the resources and machinery with the ANFF (Australian National Fabrication Facility) to help bring manufacturing back to Australia in the development and manufacture of complex machinery and electronics. With access to multiple clean rooms for device and machinery assembly.

Rolex trained case polisher and case re-finisher.

Flat polish and lapping of cases and bracelets.

Chronograph, perpetual calendar, quarter and minute repeater experts, parts hand made and CNC precision milled.

Custom-made balance staffs, winding stems and watch hands personally made by Richard McMahon..

We no longer restore watch dials for clients, we now only print and manufacture custom watch dials in enamel and precious metals for our watch manufacture.

Vintage watch expert, and advisor previously in London to Christies and Sotheby's.

Vintage OMEGA Speedmaster and Vintage Rolex, discontinued parts hand made.

Specialising in Vintage and modern Rolex (up to 2015 year), vintage OMEGA pre-1971 (lever escapements only, no Co-Axial escapements or quartz), some vintage Tudor, Cartier and Vintage Breitling. Antique pocket watches (Minimum charge $950).

Our minimum movement service charge for any repair is $950. Please see our section Service Price Guide and Information, it may answer our minimum service charges questions. We provide fixed quotes no-charge by appointment. We do not work from a fixed price list, each restoration is quoted individually. Please check with us BEFORE coming in if we can assist with your watch brand. BY APPOINTMENT ONLY.

Please contact us for VINTAGE OMEGA and Rolex restoration information on. info@rmcmahon.com.au

Laser welding, cutting and movement parts manufacture. Laser welding shown with Master Watchmaker Richard McMahon at the laser welding machine. Argon shielding and clean room micro machine parts manufacture, we offer services and manufacturing no other micro machinist or watchmaker can offer in Australia. By world standards less than 5 workshops have our complete vertical integration for complete in-house mechanical parts, movement parts or watch manufacturing in house.

One of our 3 prototyping workshop areas and workshops. Watch movement parts manufacture. Hand made enamel dials. Watch wheels, pinions, hands and case manufacture. Prototype medical instrument manufacture and small volume manufacture in medical grade stainless steel and titanium. In-house electroplating and small component anodising. We manufacture as much as we can in-house to make as high a percentage of our machines and watches as possible in the Tonsley Innovation District, South Australia and our Micro Engineering workshop McMahon Micro at UniSA, Mawson Lakes. We are adding new machinery and capabilities regularly. We undertake medical, aerospace and defence small part and machine manufacture, prototyping and testing.

Custom wristwatch and pocket watch manufacture. Cases, enamel dials and hands made in-house personally by master watchmaker Richard McMahon. Made in Adelaide, South Australia By Richard McMahon, and has been delivered to the client this year.

Our machines from Switzerland and Germany specifically for case manufacture. We cut, shape and machine case threads to manufacture water resistant cases. We do as much as possible in our watch manufacturing facilities. Our Tonsley site is mostly for enamel dial manufacture, watch case manufacturing, design and testing. It is also our customer service centre for Rolex and Omega vintage watch restoration. South Australia’s only complete watch manufacture and complete restoration centre. Micro engineering consultants and process engineering consultants for small devices in medical and defence.

Machinery used by Master Watchmaker Richard McMahon.

What does it take to manufacture an in-house mechanical watch movement? Fully equipped Swiss level micro machining watch manufacturing and restoration workshop. We manufacture device parts and watch movements and parts to micron tolerances. The best equipped specialist restoration centre in Adelaide, South Australia.

Our watch movement and micro machining workshops equipment list includes.

Siro tech German laser welder, for case repair and parts manufacture.

ONEOf Accuracy 2 Swiss timing machine, GPS calibrated daily, the most accurate timing machine in Adelaide.

3 different professional watch cleaning machines. Ultrasonic modern programmable cleaner for modern Rolex. Automatic Elma cleaning machine designed for vintage watches. Certified by OMEGA.

Programmable electronic water pressure tester, safe testing to protect the watch. Certified by OMEGA.

Enamel workshop in-house with each dial personally manufactured by Richard McMahon.

5 lathes for expert machining and milling, indexing heads for wheel cutting watch wheels and pinions, escapement parts and balance wheels.

3 complete polishing machines for case restoration and 3 ultrasonic baths for cleaning. Rolex trained case restorer.

Precision magnetism detection and de-magnetising machinery for diagnostics and testing.

Flat lapping diamond polishing equipment for first class watch case manufacture and restoration. Certified by OMEGA.

Surface scanner Olympus OLS 5000 for precision analysis of surface finish, micro measuring and quality control.

With the equipment accessed through Richard’s company McMahon Micro Machining watch manufacturing in Adelaide is on a par with ANY Swiss or international watch company.

From CNC micro machining 8 axis Willemin-Macodel mill for precision parts and movement main plate manufacture to the DMG Mori for case machining and FANUC Robodrill, a very diverse set of options for CNC machining. These parts are meticulously inspected on the Olympus OLS 5000, hand finishing and plating if required. Jewels hand fitted and adjusted. True master watchmaking.

Photo lithography in-house, we achieve nano tolerances for the smallest watch features. This is rare globally. Richard McMahon is trained in the same technology as micro chip manufacturers, right here in Adelaide, South Australia. Nano scale additive manufacture (3D printing). Richard can manufacture watch parts and movement features others simply can’t.

Clean rooms for Richard McMahon’s prototyping at our dedicated photolithography development and experimentation department partnering with ANFF at Mawson Lakes with Richard personally using ISO Class 5 & 6 labs. We are achieving tolerances using new manufacturing methods, with Richard McMahon personally developing new watch materials for novel in house escapements and other movement components. A first in Australia, and very rare globally.

Clean room access via ANFF and FII at Adelaide University for complicated medical, aerospace or defence precision device assembly, testing and quality control by Richard McMahon. With decades of experience consulting for and assisting these industries. We have assisted with medical device prototype development for engineers and scientists at Flinders University and the New Venture Institute at the Tonsley Innovation District.

Expert Omega restoration, repair and service. We are the most experienced Omega Speedmaster Professional and vintage Omega Seamaster watchmakers in Adelaide. We do not work on Co-Axial models. We complete many complicated restorations other local watchmakers say are impossible. We have many glowing customer reviews from serious watch collectors.

Rolex service and restoration. Rolex Daytona, Rolex Explorer and Rolex Submariner experts. We are Adelaide’s most experienced and qualified vintage watch restoration experts. We have decades of professional experience, working as a senior certified restorer in Europe. Richard McMahon is the only watchmaker in Adelaide to have been officially referred work by Rolex, Cartier, JLC and Breitling vintage restoration. Certified in 2001 by Cartier Bond Street and Rolex St. James Square UK for vintage restoration. We have some serious watch collectors who personally deliver highly collectable Rolex Submariner, GMT and Prince models to us in Adelaide, South Australia. Some are loyal clients I started working on private collections for in the UK and the United States. We have many 5 star reviews and testimonials for our Rolex restoration services.

Watches manufactered in Adelaide, South Australia, by Richard McMahon

Richard worked in Europe advising independent watch manufacturers as a technical expert and helped with fine tuning of some of the products we see available today as an experienced micro machinist and prototype developer, process engineering advisor. We are not able to mention the companies due to contract agreements. In 2015, founder of R. McMahon Watchmakers, Richard McMahon has embarked on a continuing journey: manufacturing Australian-made timepieces in Adelaide, with movement parts manufactured in-house for custom built movements. Cases are currently being manufactured on equipment in the R. McMahon in the Tonsley Innovation District and Mawson Lakes micro machining centre, South Australia and our design studio and UniSA and Adelaide University Mawson Lakes micro fabrication facility, partnering with the Future Industries Institute and Australian National Fabrication Facility as an Industry Representative. An exclusive list of clients has been invited to collaborate on this project with Richard. Each client will inform the aesthetic outcome of their watch – the design of the dial in hand-made enamel or precious metal, the watch hands and the size and shape of the case based on their own preference. Richard McMahon tourbillon, quarter repeater and in-house chronographs on offer, it can be expensive work, but having a watch on your wrist knowing it is one of a kind, is something pretty cool. We have completed as consultants calibres for final design and prototyping for some large companies in the ultra high quality end of the market, we estimate a few thousand watches manufactured are on peoples wrists unaware Richard McMahon was involved in the development of these special watches. In the last 12 months we have designed, manufactured and shipped over 14 watches to watch collectors. In the last ten years more than 20 watches have been delivered or exported. We have been quietly in the last 10 years been developing 2 new totally Adelaide, South Australia manufactured watch movements. We are introducing these to our new custom watch offerings. Richard McMahon, master watchmaker is offering to manufacture a completely custom watch to a customer’s specification, custom complications on request, in-house enamel dial manufacture and engraving to ensure the finished product is a world-class timepiece, native to its place of manufacture in Adelaide, South Australia. Helping to bring design, innovation and manufacturing back to South Australia. This is a rare combination of skills globally to have in one workshop, case, hands, movement and enamel dial manufactured by one master watchmaker, Richard McMahon.

Contact us regarding custom personalised Australian manufactured watch.

Please message for appointment times - info@rmcmahon.com.au

0404117186

0403586850 text for appointment

(Please text your question instead of leaving a voice message)

By appointment only.

Stainless steel and Argentium silver cases hand made in our Tonsley Innovation District workshop and AdelaideUniversity (UniSA) Micro Engineering Workshop. Watch dials hand made in our workshop in enamel, silver, gold, Lapis lazuli. Custom made hands. Manual wind, automatic and chronograph models made to order. We are now concentrating making custom manufactured watches starting at $25,000 for basic modified custom movements. In-house bespoke manual wind manufacture calibre starting at $50,000 in stainless steel.

Dial blanks hand cut, here in Adelaide, South Australia.

South Australian opal localy cut and polished. Malachite and mother of pearl cut and polished in our workshop for our custom watch manufacture. Matching hands manufactured in-house.

We have a rare mix of capabilities at R. McMahon Watchmakers and McMahon Micro Machining. Machinery like the Henri Hauser precision milling machine constructed to manufacture parts in the 1940’s for companies like Patek Philippe and Rolex. To modern CNC machines for precision miniature parts. We have the capability to manufacture our own watch cases and precision watch movement parts. In most cases the same machines used by the top factories and independent watchmakers in Europe. Along with hand made enamel watch dials made personally by Richard McMahon, it is indeed a rare facility with this combination of machinery and skills. We offer small volume prototype machine design and manufacture in-house for the medical, aerospace and defence industries. For watches we manufacture in house wheels, pinions, main plates, bridges, regulators, balance wheels, pallets, escape wheels, barrels and other movement parts to manufacture custom movements in house in Australia.

Precision manual machining is still used by Richard McMahon for rapid prototyping for testing for medical and defence if a one off piece is needed for testing. Sometimes manual machining can be faster than setting up and running CNC. We have both systems, we just weigh up speed, cost and accuracy required for the best outcome for our clients. We are on of the few micro machining workshops offering both precision systems in the one company. Very rare in Adelaide, South Australia.

Dials manufactured in Silver, gold or copper. Hand made enamel dials made personally by Master Watchmaker Richard McMahon in custom colours in our workshop at the Tonsley Innovation District, South Australia. Richard McMahon is one of only 3 independent master watchmakers globally able to manufacture in-house movements, hand made enamel dials, cases and hands. And then with complications on offer makes his workshop incredibly rare globally. True custom made rare one off master watchmaking.

Two tone matte blue and white enamel dial on sterling silver. hand made by Richard McMahon. We manufacture in custom colours, gloss or matte.

Dial flange with holes drilled to be tapped for hand made hour markers. Richard McMahon personally machining these parts, on site.

Custom manufactured pocket watch, at the mid-point of manufacture. In-house enamel dial made by Richard McMahon. Bespoke maritime style hand made stainless steel case for client. (pre-engraving). Suspended hour indicator battons. An example of in-house manufacture.

Hand made enamel dial, case and hands by Richard McMahon in his Tonsley workshop, Souh Australia. Richard McMahon personally manufactures each enamel dial. For yhis custom military/industrial style one off custom commission Richard McMahon elected to manufacture the case on manual lathes snd milling equipment, from 316L stainless as specified by the client. For some manufacturing it is more efficient to use traditional machines rather than a CAD drawing, machine set up and CNC run time. For more complicated cases with flat, complex features and threaded case backs Richard McMahon will create a CAD drawing, export a file to a selected 3, 5 or even 8 acis milling machine. Having that choice and personal control gives R McMahon Watchmakers the creative edge to complete very complex modern and traditional designs. By the way the client was delighted with the finished watch, it was a very special and personal gift to himself.

In house prototype being tested before new balance wheel and regulator manufacture, movement finish in grey, blue, yellow or rose gold and rhodium. It is a rare thing movements being manufactured in the Southern Hemisphere. We at R. McMahon Watchmakers a rare manufacturing workshop building our own movements, not just importing parts and labelling as Australian Made.

We manufacture our own enamel dials in-house at our Tonsley workshop in South Australia. These are test colours fir colour matching. We matched an enamel dial here to a clients Porsche colour paint. We got a near perfect match in gloss enamrl with a depth of colour matching his 911 SC classic. (Stunning car by the way). Richard McMahon may test fire 2 or 3 Stirling silver plates to get the colour correct and chart temperatures and kiln time. This takes many years of practice and experimentation. Each one is an individual work of art. We believe only 2 workshops glibaly have a master watchmaker able to manufacture a movement, case, hands, enamel dial and other essential parts that are fabricated within the same studios by the same master watchmaker. With over 35 years experience manufacturing all watch parts for restoration work as an expert and slowly iver the last 20 years building these individual disciplines within one watch has been a many thousands of hours journey, but worth every second because Richard McMahon loves beautiful watches.

Sterling silver matte finish enamel dials hand made by personally Richard McMahon in our Tonsley workshop. Series 1 manual wind shown here. First series pre-sold, complete and delivered. Hand made watch case. With screw on back, sapphire crystal glass.

Hand made enamel watch dials made in-house by Richard McMahon.

Manual wind prototype with custom manufactured parts being tested, an early stage before custom regulator and new drive wheel and main plate was manufactured in-house by Richard McMahon. We still offer hand made cases and dials with heavily modified Swiss movements, but our main focus going forward is our in-house movement manufacture. This series Tonsley has already sold and delivered ahead of schedule. We have a track record of manufacturing very complicated in-house parts, wheels, pinions, manipulates and bridges. Chronograph levers, springs and wheels hand made by master watchmaker Richard McMahon. Date and calendar disks machined, engraved and printed in house with jumper springs and day/date wheels and cams made in house by R McMahon. Toubillon carriage, pinions and lever pallets manufactured and assembled in our micro precisiin machine centre in South Australia, designed by Richard McMahon to exacting specifications. Our own balance wheels and escapements. As with any watch manufacturer off the shelf jewels are purchased and then modified to custom shape and fitting. We still purchase hairsprings and modify for our own purpose and technical requirement, this is the norm even in master watchmaking workshops around the world. It is in these cases not a matter of purchasing parts and fitting them, many hours of R & D and testing still is required for our in-house movements. Richard McMahon is currently completing prototyping on a rare alarm and repeating design with him manufacturing by hand the gong and sounding bell with hand polished hammers and gearing system. We believe this will be a first in the Southern hemisphere and matches with an enamel dial hand fired by McMahon very rare globally as a combination.. We are not aware of any watch manufacturer globally at 100% content in custom manufacture. We strive to get as close to 100% as possible with only the same limitations ad lhe largest most established watch manufacturers. We are regularly asked to respect our watch collectors privacy snd publish photos of completed watches if requested. Some serious collectors prefer to remain anonymous and have their name added to the finished custom watch. We are happy to keep these relationships private. We are used to operating under NDA’s for our micro machining work for industry as we have for decades. Own a rare custom made wristwatch made in house in Australia knowing nobody else has the same custom made watch by Richard McMahon. Our most basic watches still start at $25,000 for the next few months. From December this year we will be only offering one off custom Richard McMahon manufacture. Timepiece with enamel dial will start at $50,000. Alarm or chronograph will start at $85,000 with hand made enamel. Other combinations will exceed $120,000. Build times start at 3 months from deposit payment for timepiece with enamel dial and complications like date and day models currently 6 to 9 months. Full custom complications like Toubillon and chronograph approximately 9 to 12 months depending on complexity and our other order list. A deposit on proceeding with full design work and starting manufacture requires a 30% to 50 % deposit depending on the build and materials required. A design book with CAD technical drawings and manufacturing photos of tour watch are supplied on completion. A workshop tour on signing to proceed and a tour near final assembly stage is welcomed unlike other master watchmaking workshops. Existing clients only are permitted by appointment for privacy and safety reasons, we also observe high standards of cleaning and some areas are restricted as our cleanrooms are viewable through glass but not accessible without a dust suit.

Cases hand made in our workshop based in Tonsley South Australia and Mawson Lakes South Australia. Stainless steel, titanium, silver, gold and aluminium on manual lathes and mills.. Wilemin-Macodel 8 axis CNC machine milling and DMG Mori 3 axil and multi axil FAUNC Robodrill alongside manual hand finishing in Richard McMahon’s micro machining workshop McMahon Micro partnering with ANFF and the Future Industries Institute Adelaide University as an Industry Representative. These cases are some of our prototyping cone in-house on manual machines at our Tonsley workshop and test cases for our new mechanical alarm and calendar complication model.

Custom built pocket watches starting at $25,000. Wrist manual wind chronograph with in house manufactured case and enamel dial starting at $25,000.

Note, Tonsley Watches are no longer available. All have been allocated and pre-sold. We still offer our one off custom watches.

R. McMahon custom.

Our first series introductory prices have all been allocated, and delivered ahead of schedule.

Changes and alterations will be charged accordingly.

Precision large manual mill used by Richard McMahon for case and tooling manufacture. Sometimes big machines are needed to make small precision watch parts. Our machinery is distributed between our micro machining centre McMahon Micro with the ANFF Adelaide University in Mawson Lakes and our prototyping and testing facility at the Tonsley Innovation District.

Willemin-Macodel precion 8 axil mill for making main plates, movements, bridges, wheels and pinions and escapement parts. We manufacture balance wheels and escapement parts, hand finish and spend many hours assembling, testing precision and surface finish on the OLS 5000 to ensure accuracy. Micro machining centre for the same level of manufacturing as the Swiss, German and Japanese manufacturers, simply because we use the same machines. We actually manufacture in Australia, not importing cases and dials from Germany or Asia as other companies do. Workshop tours organised of our Mawson Lakes and Tonsley facilities for clients proceeding with custom manufacture. See the real deal in Australian watch manufacture. Master watch maker Richard McMahon. Our combination of in house movement, case, hands and enamel dial manufacture is VERY rare anywhere in the world.

The Robodrill is a great machine for manufacturing complex profiles and shapes for case manufacture, once the general case shape is complete, Richard McMahon will either polish or satin finish the case, complete strap attachment holes and either thread for a screw back or other custom case back fittings. We manufacture is solid or exhibition backs with a sapphire crystal, depending on requirements. Watch movement main plate blanks manufactured on this machine and transferred to the precision Wilemin-Macodel multi axis machine for jewel holes and pockets for wheel and lever fitting. Every machine is important and each precision process checked for quality on the OLS 5000 before proceeding to the next step. This is done here in the he machine centre, Richard McMahon does not import cases, he makes them.

Commissioning a Watch by Master Watchmaker Richard McMahon.

Custom in-house Watch Manufacture by Master Watchmaker Richard McMahon. Exclusive and rare hand made movements, cases, enamel dials and hands. Timepiece, complications like GMT, chronograph, alarm and toubillon built by hand in our Tonsley and Mawson Lakes micro machining workshops.

We produce only a handful of custom watches each year.

Typical delivery: A total combination of 12 wrist and pocket watches produced annually.

Lead time: 6 - 12 months depending on complexity of the movement manufacture.

Starting price: Manual wind in-house movement with over 95% manufactured by Richard McMahon, with hand-made enamel dial and stainless steel case also personally made by Richard $50,000. AUD. Alarm or chronograph starting at $85,000. AUD. We are just announcing our in-house GMT with enamel dial by master watchmaker Richard McMahon. Starting at $55,000 we are taking orders now for April 2026 delivery.

As mentioned on the page by 1 January we are phasing out base level custom with Swiss heavily modified precision movements made by R McMahon (over 80% in-house manufacture), last orders by December 31st. From January we will only offer tier 1 with 95% in house manufacture, and tier 2 with 85% in-house with Swiss made escape wheel and pallets. The prices for full custom will obviously differ as few master watchmakers globally either have the equipment or have the skills to do so, we have both.

Other complications on offer can be discussed, like toubillon and repeaters. We have manufactured Toubillon and repeater in-house for clients. We are just commencing our first in-house perpetual calendar hand-made watch, please enquire by email to get on the first manufacture wait list, only 3 will ever be made by Richard McMahon, one is already allocated and pre-sold. We are happy to discuss builds, any pricing, delivery and deposit terms are strictly discussed and confirmed by email.

Deposits on proceeding after a basic draft design is between 30% and 50% depending on complexity and materials chosen by the client.

Each commission is private, no sharing of designs or custom manufacture at the clients request. We are used to a process of not publishing private commissions as we have for decades with our custom work for well known international watch companies and jewellers. Our work is inside many watches without our brand or logo. We know, that is all that matters.

“To wear an R. McMahon watch is to own a piece of Australian horological history-a timepiece conceived, built, and hand finished by a single master watchmaker-Richard McMahon.”